Removing “bottlenecks” in the localization of automotive components and parts: To be resolved soon

19/04/2022Currently, only a few domestic component suppliers can participate in the supply chain of automobile manufacturers and installers in Vietnam. This reality will gradually improve as domestic automakers commit to continue raising the localization rate and supporting the development of local suppliers.

On April 12, 2022, the Center for Industrial Development Support (IDC Center), the Department of Industry – Ministry of Industry and Trade and Toyota Automobile Company of Vietnam jointly organized the online negotiation “Program to find and connect suppliers of the Department of Industry and Toyota”, within the framework of the annual cooperation project between the Department of Industry and Toyota Automobile Company of Vietnam from 2020 to support Vietnamese enterprises in the field of automotive industry.

Anxiety with the story of connecting supply and demand

According to the Department of Industry, supporting industries (CNHT) are recognized as a sector that plays a very important role in economic development, is a direct driver of value-added, increasing the competitiveness of industrial products and accelerating the national industrialization process.

During the past time, the Government’s synchronous implementation of solutions to support organic agriculture enterprises has contributed to improving the competitiveness of enterprises, improving productivity and product quality, supporting trade connections, contributing to meeting the demand for domestic production.

In addition to the excellence of the whole industry in general, the development of CNHT has achieved some encouraging achievements, but in the context of integration and the global economy is facing many challenges due to the Covid-19 epidemic that has been causing all economic sectors, including Vietnam’s CNHT sector to face many difficulties.

Statistics from the Department of Industry show that Vietnam currently has 2,000 enterprises producing spare parts and components, of which only about 300 enterprises participate in the production network of multinational corporations, the localization rate in many industries is still low.

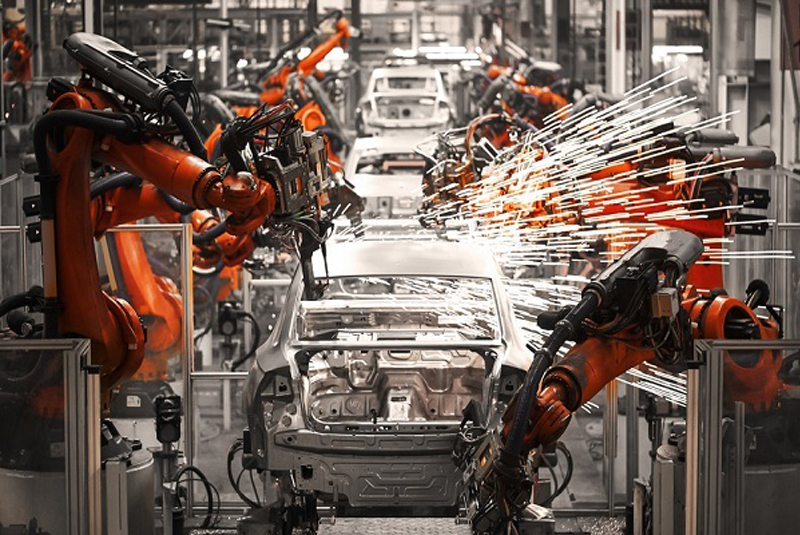

For this situation, especially about the automotive industry, Mr. Cao Van Binh – Deputy Director of the Center for Industrial Development Support (IDC) – shared: “One of the biggest weaknesses of the Vietnamese economy is the limited production capacity, which depends greatly on foreign supply chains. Automotive parts currently in production in Vietnam are mainly labor-intensive parts, simple technology. On the other hand, in the past time, the first – last link in the production chain is still not really tight, the business is still loitering with the story of connecting supply – demand. Currently, only a few domestic suppliers canparticipate in the supply chain of automobile manufacturers and installers in Vietnam. ”

Starting from the problems that need to be removed and solved for the CNHT industry mentioned above, the Industrial Department has joined Toyota Vietnam Automobile Company in implementing the project of developing the production capacity of manufacturing enterprises to get closer to the automotive supply chain at home and abroad.

According to Toyota Vietnam Automobile Company, the Cooperation to support domestic enterprises in the field of CNHT includes 4 main activities: Screening manufacturing enterprises and preparing a list of potential suppliers of automotive spare parts and components to connect with automotive assembly manufacturers in Vietnam; Searching and supporting potential suppliers of levels 2 and 3 and introducing to the first-level suppliers from the data of screening activities; Support training participation according to some Vietnamese supplier development programs.

Previously, Toyota Vietnam has participated in supporting the training of industrial enterprises supporting the North and Central regions under the Vietnam Supplier Development Program in the field of automotive, electronics and mechanical engineering held at the Center for Industrial Development Support – Industry Department in July, October and November 2021. The cooperation is expected to bring many practical values, contributing to improving capacity, increasing access to global production chains for Vietnamese industrial enterprises.

Efforts to find and connect suppliers

With the motto of commitment to long-term production and development in Vietnam, Mr. Junichiro Yamamoto, Director of Toyota Vietnam Administrative Division – said that during the development process in Vietnam from its establishment to now, according to the orientation of the Government, Toyota Vietnam always strives to contribute to the development of the Vietnamese automotive support industry and constantly strengthen the domestic supplier network to develop the industry long-term.

In the period of 2020 – 2021, despite many difficulties caused by the COVID-19 pandemic, Toyota Vietnam still recruited 12 new suppliers out of a total of 46 suppliers (including 6 pure Vietnamese suppliers). To date, the enterprise is the manufacturer of FDI automobiles with the highest localization rate with more than 724 components (such as body, chassis, seat, battery…). In the period of 2020 – 2021, 324 new components were localized.

Also in 2022, Toyota Vietnam aims to add more new suppliers and more than 200 new localized components.

To promote localization is not merely to increase the number of Vietnamese suppliers but more importantly to improve the capacity and quality of suppliers, thereby reducing production costs and increasing competitiveness. Toyota Vietnam has been looking for potential suppliers and connecting with enterprises operating in Vietnam, sharing supplier development experience, introducing supplier models that Toyota has supported to other component suppliers to learn, thereby gradually building supply chains in the support industry, improving the capabilities of domestic suppliers.

To accompany the business to become a supplier, Toyota Vietnam not only purchases but also works directly with the supplier, self-developing employee capacity, guiding the supplier towards lean production. Activities to create a safe working environment, arrange and eliminate unnecessary stitches, focus on standardizing the work and moving towards increased performance.

In addition, the Department of Industry also recognizes that through this cooperation project, Vietnamese enterprises have the opportunity to access to global supply chain standards, thereby gradually improving their competitiveness, meeting the strict requirements of customers not only in terms of price, technology, quality, delivery but also social responsibility requirements related to safety, environment and labor conditions.

| The Bureau of Industry said that in 2022, the Bureau will work closely with a number of multinational FDI enterprises such as Samsung, Toyota… to strengthen the search and connection of domestic raw materials and components manufacturing enterprises that can produce import replacement in the short term as well as in the long term. |

Source: Cong Thuong

Must Read

2023 PARTICIPANT LIST

[Seminar] INDUSTRIAL METROLOGY

MTA Vietnam 2022 Webinar

ADB is optimistic about Vietnam’s economy

MTA Vietnam 2021 x Bystronic Webinar

CONFERENCE SERIES

ONLINE BUSINESS MATCHING PROGRAMMES

You may be interested in

Vietnam is a potential market for companies engaged in the manufacturing of agricultural machinery and equipment

‘The Giant’ Goertek is expected to invest over 6,800 billion VND in Vietnam to expand production. Which locality will be chosen?

Electronics Industry: Seizing Opportunities for Breakthroughs

The force for processing and manufacturing industry

Ho Chi Minh City promotes research and development of artificial intelligence

AI Application Trends in Industrial Automation

Vietnamese AI expected to contribute 14,000 trillion dong by 2030

Apple could be relocating significant iPad engineering resources to Vietnam